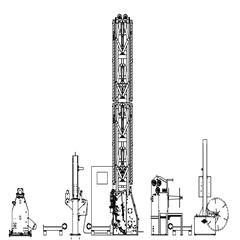

Basic Technical data for whole vertical impregnation line

1.0 General

NTRY-300V-8-EGCM vertical impregnation line designed to produce polyester and fiberglass mesh impregnation, consisting of an unwinder, web jointer, foulard, infra-red heating web heating Chambers, tractor, cutter and rewinders.

| Raw web crane |

|

Max. loading 3tons |

| Raw web size |

2800mm |

Fiberglass |

| Finishing web size |

1188 1273mm fiber glass impregnated |

Max. roll diameter 1500mm |

| Rollers |

1520mm max. width |

|

| Expanding shafter |

3” or 6” or requested diameter |

76mm or 152mm or others requested |

| Mechanical speed |

50m/min designed |

|

| Performance speed |

30m/min max |

Speed will reduce in heavier web cases accordingly |

| Heating capacity |

230kw |

|

| Heating reflecting panels |

8groups |

Nos.16 pcs in 500mm each |

| Heating effective Channel |

16meter |

Reversing Channel |

| Cutting before rewinder |

3knives |

Nos.1 centering and nos. 2 as margin strips |

| profile |

9000 * 5500 * 6340mm |

|

| control |

Siemen & Schneider & Taiwan & Japa |

Touch screen, Siemens |

2.0 Details of units

2.1 Un-winder

| 1 |

Width adjustable single roll unwinder |

Nos. 1 |

| 2 |

Web guiding roller |

Nos. 3 |

| 3 |

Button recall electronical web aligner |

Nos. 1 |

| 4 |

Safety disc chucks |

Nos. 1 |

| 5 |

6” air expanding shaft for raw web |

Nos. 1 |

2.2 Raw web crane

| 1 |

Crane frame structure |

I-beam |

| 2 |

Crane loader |

5tons |

2.3 web jointer platform

| 1 |

Operator flatform |

Nos. 1 set |

| 2 |

Guiding rollers |

Nos. 1 set |

2.4 web jointer

| 1 |

Jointer main frame |

Nos. 1 |

| 2 |

Guiding and touching rollers |

Nos. 4 |

| 3 |

Pneumatic lifting device |

Nos. 1 |

| 4 |

Automatic hot stamper |

Nos. 1 |

| 5 |

Temperature ctrl. |

Nos. 1 |

| 6 |

Locking and press device |

Nos. 1 |

2.5 platform ahead of impregnator

| 1 |

Operator flatform |

Nos. 1 set |

| 2 |

Guiding rollers |

Nos. 1 set |

2.6 impregnation unit/Foulard

| 1 |

Impregnator main body/heating chamber bottom |

Nos. 1 |

| 2 |

Resin content pickup adjustable device |

Nos. 1 set |

| S.S impregnation positive rollers nos. 1 set, rubber touch rollers nos. 2 set, pneumatic resin apply nos. 1 |

| 3 |

Resin bath liftable device |

Nos. 1 set |

| 4 |

Resin bath liquid leveling, and filtering recycle |

Nos. 1 |

| 5 |

VF ctrl driven |

5.5kw |

| 6 |

Web guiding rollers |

Nos. 4 |

| 7 |

Mesh blind blower |

Nos. 1 |

2.7 heating Chambers and exhausting.

| 1 |

Heating chambers nos. 4 * 2 ( L * R) |

Segment height 1000mm |

| 2 |

Foldable heating panel |

Infra-red panel, 500mm, nos. 16pcs |

| 500mm per pcs instead of 1000mm, easier for maintenance |

| 3 |

Heating capacity |

230kw in total |

| 4 |

Overheating protection, pneumatic driven hinged traverse mechanism |

Nos. 8, protecting web in stops |

| 5 |

SCR automatic temperature ctrl |

Nos. 16 |

| 6 |

Top turn-over rollers |

Nos. 2 Teflon coated rollers |

| 7 |

Exhausting hood |

VF ctrl. Nos. 1 |

| 8 |

Exhausting motor |

10.75kw |

| 9 |

Heating oven insulation |

100mm, AlSiO3 |

2.8 Heating Chamber labor platform

2.9 Tractor

| 1 |

Tractor main structure |

Nos. 1 |

| 2 |

Driven roller |

Nos. 2 |

| 3 |

Guiding roller |

Nos. 4 |

| 4 |

Tension sensor |

Nos. 1 |

| 5 |

VF driven |

7.5kw |

2.10 finishing web accumulation (passive)

| 1 |

Web accumulator main structure |

Nos. 1 |

| 2 |

Comb floating up/down web storage |

Nos. 1 |

| 3 |

Safety limits sensor |

Nos. 2 |

| 4 |

Web storage |

50m |

2.11 Rewinder

| 1 |

Transverse rewinder main structure |

Nos. 1 set |

| 2 |

Web aligner |

Nos. 1 set |

| 3 |

Main center cutter |

Nos. 1 set |

| 4 |

Margin cutter |

Nos. 2 set |

| 5 |

Counter roller rewinder with touching roller and synchronization trail |

Nos. 1 set |

| 6 |

Length auto metering |

Nos. 1 set |

| 7 |

Margin cutter stripes collector |

Nos. 2 set |

| 8 |

Air expanding shafts 6” |

Nos. 2 pcs |

2.12 Rewinder hanging crane

| 1 |

Crane frame structure |

I-beam |

| 2 |

Crane loader |

5tons |

Operating Video link:

https://youtu.be/A10yVkvoRXI